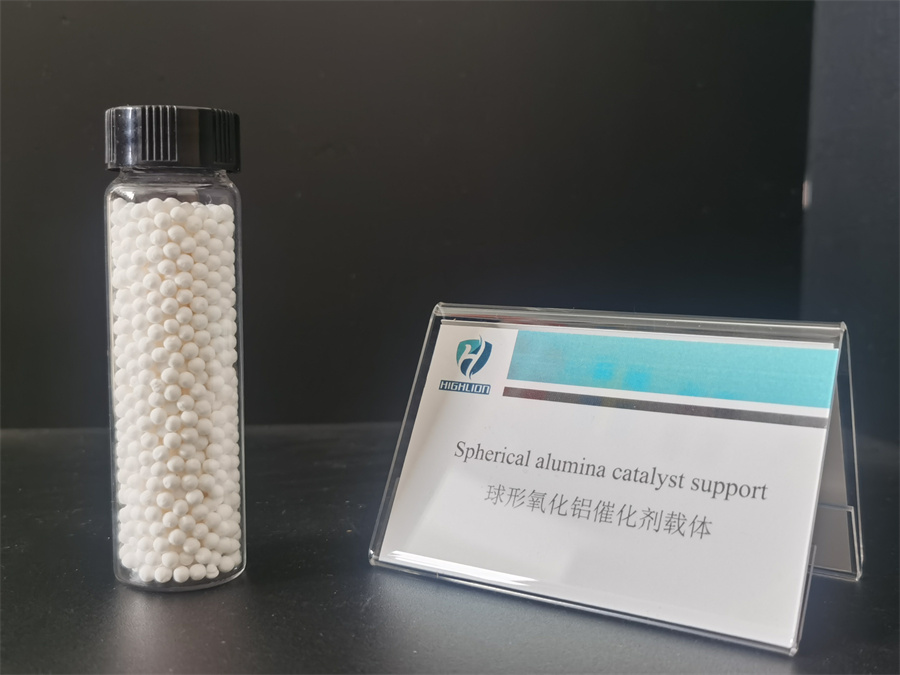

Gamma-alumina spherical shape carrier/support advantage

Spherical alumina catalyst carrier/supports offer significant advantages over other shapes (such as cylindrical, extruded, pelletized, or irregular particles) in industrial applications, particularly in terms of fluid dynamics, mechanical strength, and active component dispersion.

1. Spherical supports are ideal for continuous-flow reactors (e.g., fixed-bed, fluidized-bed), reducing energy consumption and improving reaction efficiency.

2. Spherical supports last longer in high-pressure or high-flow systems, reducing downtime for replacement.

3. Spherical supports maximize active site exposure, minimizing waste of precious metals (e.g., Pt, Pd).

4. Spherical supports enable automated packing and optimize reactor volume utilization.

5. Special Application Scenarios

– Fluidized Bed Reactors: Spherical supports are almost mandatory (other shapes are difficult to fluidize).

– Fixed-Bed Reactors: Spherical > Extruded/Cylindrical (lower pressure drop).